-

Our program covers the specific hazards related to the use of propane in everyday use. For example; forklifts, torches, BBQ’s, heaters, small stoves, and much more applications. It provides participants with information on how to safely connect, disconnect, and the activation of propane equipment in the workplace.

Our program covers the specific hazards related to the use of propane in everyday use. For example; forklifts, torches, BBQ’s, heaters, small stoves, and much more applications. It provides participants with information on how to safely connect, disconnect, and the activation of propane equipment in the workplace. -

At C&R Safety Training Solutions we offer a certified Power Tool Safety and Hazard Prevention Training. Power tools and equipment, both stationary and portable (hand-held), are commonly used in several industries. We have resources on working safely with many types of power tools, including chainsaws, circular saws, grinders, nail guns, and more.

At C&R Safety Training Solutions we offer a certified Power Tool Safety and Hazard Prevention Training. Power tools and equipment, both stationary and portable (hand-held), are commonly used in several industries. We have resources on working safely with many types of power tools, including chainsaws, circular saws, grinders, nail guns, and more. -

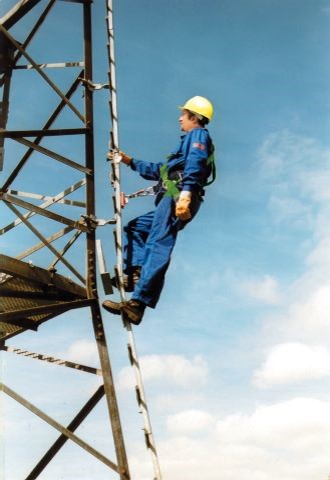

Our Ladder Safety course provides users with the knowledge and understanding of all the different types of “ladders” and how to use the appropriate ladder for a specific task. Nearly 20% of all lost time injuries (time lost for the worker) can be contributed to falls in the workplace. The majority of injuries are same level, others are lower level. Ladders contribute to the more serious injuries or death. In fact, only motor vehicles contribute to a higher risk of workplace validities. You may have never personally experienced a fall but that doesn’t mean that hazards don’t exist; It’s imperative that worker know the hazards working with “ladders” and consistently follows rules and safety work procedures and don’t become another statistic.

Our Ladder Safety course provides users with the knowledge and understanding of all the different types of “ladders” and how to use the appropriate ladder for a specific task. Nearly 20% of all lost time injuries (time lost for the worker) can be contributed to falls in the workplace. The majority of injuries are same level, others are lower level. Ladders contribute to the more serious injuries or death. In fact, only motor vehicles contribute to a higher risk of workplace validities. You may have never personally experienced a fall but that doesn’t mean that hazards don’t exist; It’s imperative that worker know the hazards working with “ladders” and consistently follows rules and safety work procedures and don’t become another statistic. -

C&R Safety Training Solutions is dedicated to your Health & Safety, our Lead Hazard Awareness course is designed to educate the learner in the awareness of working around lead. Lead is one of the most common toxic elements found in industry and is a leading cause of workplace illness. According to the Centers for Disease Control & Prevention, despite improvements in public health policies and substantial reductions in blood lead levels (BLLs) in adults, lead exposure remains an important health problem worldwide. Nearly every construction trade has the opportunity for potential exposure to lead during “normal” construction tasks including carpenters, electricians, ironworkers, painters, plumbers, sheet metal workers, among others.

C&R Safety Training Solutions is dedicated to your Health & Safety, our Lead Hazard Awareness course is designed to educate the learner in the awareness of working around lead. Lead is one of the most common toxic elements found in industry and is a leading cause of workplace illness. According to the Centers for Disease Control & Prevention, despite improvements in public health policies and substantial reductions in blood lead levels (BLLs) in adults, lead exposure remains an important health problem worldwide. Nearly every construction trade has the opportunity for potential exposure to lead during “normal” construction tasks including carpenters, electricians, ironworkers, painters, plumbers, sheet metal workers, among others. -

C&R Safety Training Solutions offers a half-day course on machine guarding. When machines are not properly guarded or locked out during maintenance, repair and other activities at industrial sector workplaces, workers can be exposed to several hazards. These hazards can result in serious injuries such as amputations of limbs or death. Hazards can include:

C&R Safety Training Solutions offers a half-day course on machine guarding. When machines are not properly guarded or locked out during maintenance, repair and other activities at industrial sector workplaces, workers can be exposed to several hazards. These hazards can result in serious injuries such as amputations of limbs or death. Hazards can include:- Exposure to in-running nip hazards, i.e. getting caught up in machinery and moving parts if equipment is not properly guarded.

- Exposure to hazardous motion, such as rotating machine parts, if equipment is not properly locked and blocked during maintenance and repair.

-

This course is designed to help workers, supervisors and workplaces establish and implement a safe work procedure to unwanted electrical, hydraulic, pneumatic, kinetic and potential energy sources that cause injury or death in the workplace.

Course Content

- Hazards involved with improper lockout tag out procedures

- Rights and responsibilities of all workplace parties according to the Act

- The 6-step process to lockout tag out

- Understanding energy sources

- Implementing policies and procedures

- Preparing an action plan

- Recognize, assess and control of all parties to related hazards

-

At C&R Safety Training Solutions we are committed to the health and safety of everyone involved we it comes to moving large and heavy equipment and materials when hoisting. In many industries, when the movement of a large object is required, a crane is brought in to help lift the load. In many ways, cranes are helpful and convenient pieces of equipment. But we can’t forget that cranes are also dangerous, especially when the load they will be carrying has not been rigged properly.

At C&R Safety Training Solutions we are committed to the health and safety of everyone involved we it comes to moving large and heavy equipment and materials when hoisting. In many industries, when the movement of a large object is required, a crane is brought in to help lift the load. In many ways, cranes are helpful and convenient pieces of equipment. But we can’t forget that cranes are also dangerous, especially when the load they will be carrying has not been rigged properly. -

Our program at C&R Safety Training Solutions is designed for persons operating heavy equipment in on-site specific workplaces. The training will cover a combination of on-the-job and classroom training. The operator/trainee must pass the classroom training and written test as well as pass a demonstration of skills such as operating a front-end loader, backhoe, excavator, bulldozer, skid-steer and crawlers on-site demonstrating a pre-equipment inspection, start-up procedures, safe operation, and shut down procedures.

Our program at C&R Safety Training Solutions is designed for persons operating heavy equipment in on-site specific workplaces. The training will cover a combination of on-the-job and classroom training. The operator/trainee must pass the classroom training and written test as well as pass a demonstration of skills such as operating a front-end loader, backhoe, excavator, bulldozer, skid-steer and crawlers on-site demonstrating a pre-equipment inspection, start-up procedures, safe operation, and shut down procedures.